- 22nd December 2023

- Manufacturing, Southern

- CNC machinery, southern 2024

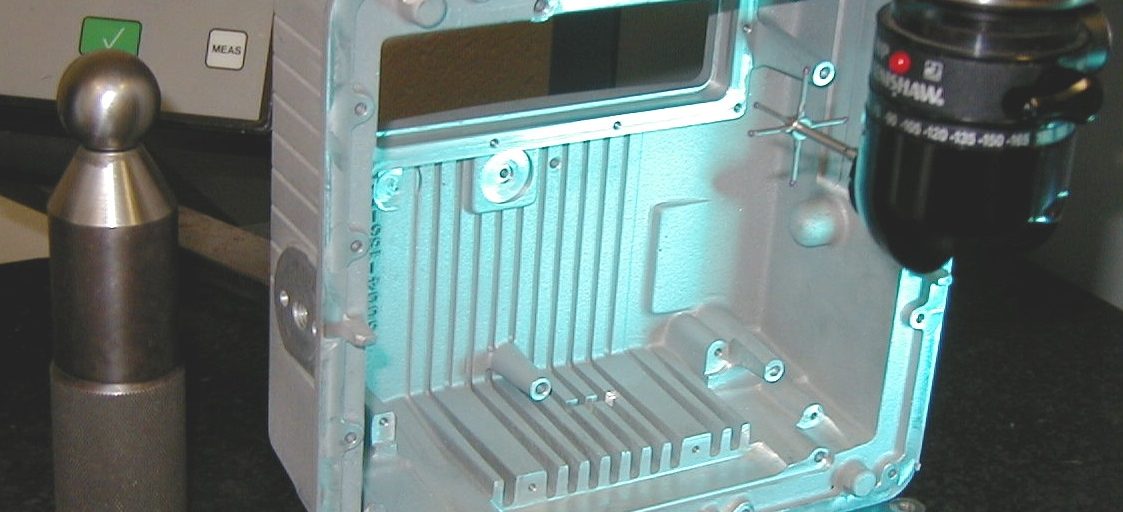

Norse Precision Castings capabilities range from as cast to complete

Low to medium volume precision aluminium sand castings have been available from Norse Precision Castings since 1977. The company offers both ‘as cast’ and machined and painted to ‘complete supply’ including sub-assembly precision parts. It is able to operate as a one-stop shop with fast and cost-effective manufacturing of complex shapes and patterns. Wall thickness are 3mm with tolerances of ±0.4mm.

Low to medium volume precision aluminium sand castings have been available from Norse Precision Castings since 1977. The company offers both ‘as cast’ and machined and painted to ‘complete supply’ including sub-assembly precision parts. It is able to operate as a one-stop shop with fast and cost-effective manufacturing of complex shapes and patterns. Wall thickness are 3mm with tolerances of ±0.4mm.

The ,company’s well-equipped factory accommodates in-house heat treatment using electric top-loading ovens and water quenching. It also offers a variety of finishing processes include shot blasting, glass bead blasting, anodising and impregnation.

There is a dedicated facility within the Bedford site which provides wet and powder coating, with two 5m spray booths and curing oven, together with degreasing equipment and separate masking, inspection and packaging areas. The in-house CNC machining facilities include seven CNC vertical machining centres with capable table widths between 500mm to 1100mm, complemented by co-ordinate measuring machine (CMM) inspection reports.

Norse also manufactures rigid polyurethane mouldings for low to medium volume production and components can also be supplied in painted and sub-assembled condition if required.

Other capabilities are reverse engineering services. The company serves a range of industries including medical (testing and diagnostics), laboratory (analysis and measurement), classic vehicle components, architectural (structural and decorative), marine, electric vehicles, motorsport and electronics.

Visit Norse Precision Castings

Stand N115