- 7th December 2020

- Auto/Aero, Electronics, Exhibitor Announcements

- Cables, Components, Connectors, South2021

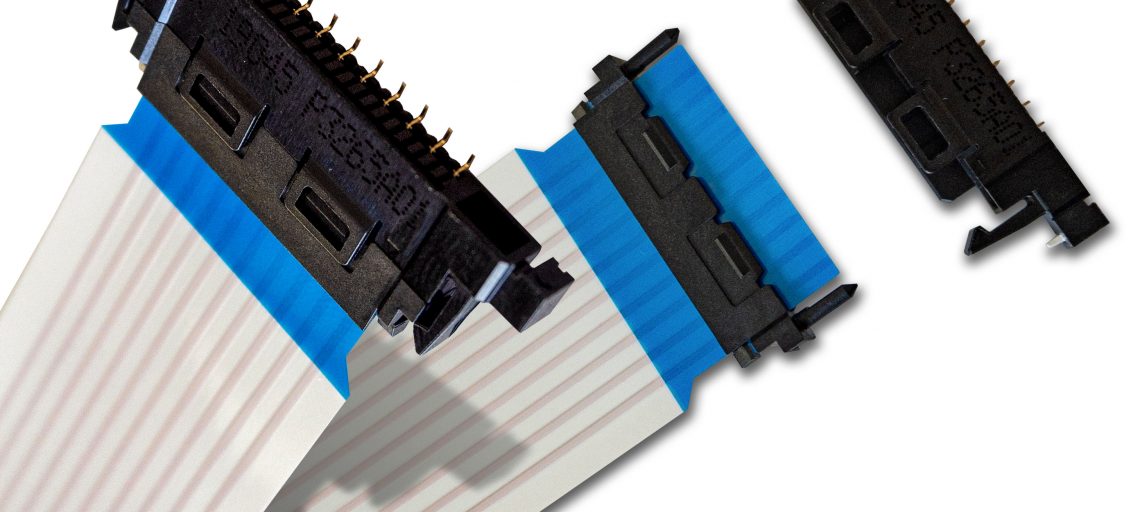

Yamaichi announces the latest versions of its flexible flat cabling system connectors.

Yamaichi Electronics’ flexible flat cabling (FFC) system and its Y-Lock connectors have been widely used in numerous automotive applications, such as infotainment, camera systems, car computing, antennas, TV, navigation, radar and lidar as well as battery management systems. The Y-Lock series is a board-to-cable system and is now available in 3 different versions. The connectors and associated cabling are produced at Yamaichi’s own ISO TS16949 certified manufacturing sites in Germany.

The Y-Lock concept is particularly suitable for space-critical installation situations, permitting secure connections, even in the absence of visual contact, using either manual or automated insertion. Another advantage of the Y-Lock series is the greatest possible security of the contact coverage between FFC pads and connector. The contact coverage is provided by the FFC guide rails in the connector. This facilitates even more the FFC guiding by the stiffener which positions the FFC. That makes it simply impossible for the FFC to be crooked, which is always a possibility when using ZIF connectors. That means there is no danger of a lack of contact coverage.

The non-ZIF-based Y-Lock connector is noted for its locking system, which works without opening or closing a flap or drawer and without actuating an unlocking mechanism. In the current version 1, the interlock is provided with a ratchet hook on the housing of the connector, which engages behind the supporting tape of the FFC/FPC. Both contacting and removal of the FFC are very simple using a defined pull-out force.

The Y-Lock version 2 retains all the positive features of version 1, but also offers some interesting new features. An additional plastic stiffener has been added that is mechanically assembled with the FFC. The stiffener then engages with the connector. This new system makes guiding the FFC and inserting the FFC into the connector more convenient. The pull-out force for the FFC has also been increased from about 10N to about 25N.

Version 3 is equipped with additional locking mechanisms for an even better contact reliability in critical applications. The additional locking mechanism features both lateral and frontal latches. Due its robust design this version is particularly in demand for battery management systems.

All 3 versions were specifically designed for demanding automotive or industrial applications subject to exposure to vibration, shock and harsh climatic requirements over a temperature range of -40 to +105 °C. The Y-Lock series meets the requirements for the demanding LV 214 automobile standard.

Version 2 of the Y-Lock Pullforce is available as 18 and 50-pin variant with a pitch of 0.5mm and a connector orientation of 180°. Other pin counts and design variants are available upon request. This allows the practical expansion of the already wide range of version 1. Version 1 is available in pitches of 0.5 and 1.0mm as well as with 12 to 30 contact pins in 90° and 180°. Currently version 3 is available as 20-pin version with 1.0mm pitch or as 10-pin version with 2.0mm pitch. The series are enhanced continuously by new pin-counts. Yamaichi Electronics offers the matching FFC´s for all 3 versions, with or without additional stiffeners. Samples of all versions including the FFC are available upon request.

You can meet Yamaichi Electronics at Southern Manufacturing & Electronics 2021 on stand E170 or find out more at www.yamaichi.eu