- 11th December 2023

- Manufacturing, Southern

- CNC machinery, robotics, southern 2024

Thame Workholding partnership bring VersaBuilt robotic CNC to UK

In addition to chucks, vices, soft and hard jaws, t-nuts, height pins and other workholding accessories provided by Thame Workholding (TEC), the company has recently expanded its offering, providing automation solutions for engineers.

In addition to chucks, vices, soft and hard jaws, t-nuts, height pins and other workholding accessories provided by Thame Workholding (TEC), the company has recently expanded its offering, providing automation solutions for engineers.

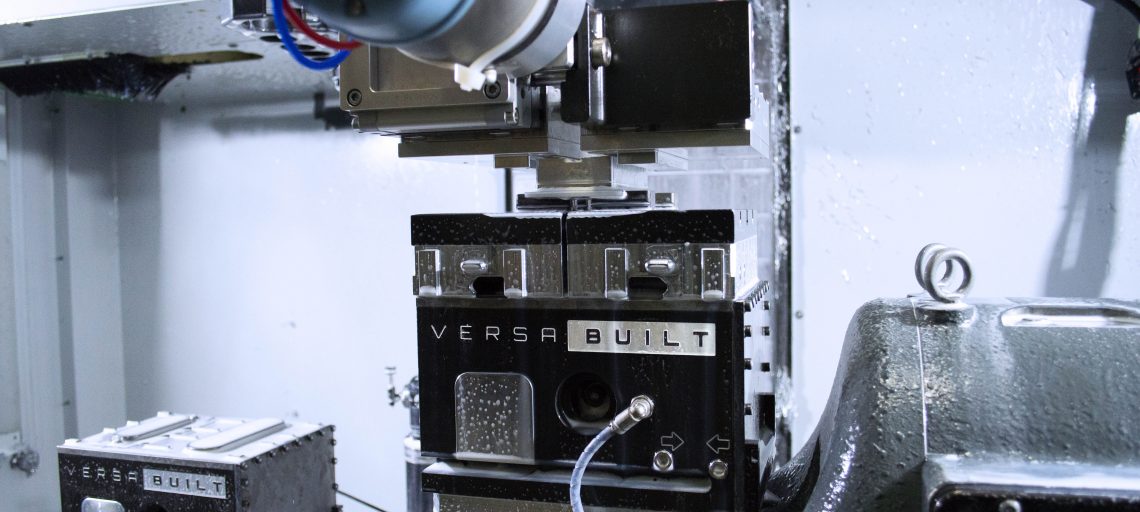

The latest sales partnership is with US-based VersaBuilt brings robotic CNC machine tending systems for “high-mix CNC production”. The offering includes a MultiGrip vice and jaw system which effectively combines the role of the robot gripper with the workholding jaw and then integrates it with the UR cobot’s arm. Unlike other systems, the vice jaws are removed by the robot arm and then used as the robot gripper so there is no need to make special grip fingers or have first and second operation grippers.

The entry level system loads into relatively standard CNC machines and is suitable for small to medium-sized engineering companies that want to automate the production of comparatively simple components.

Thame Workholding designs and manufactures the majority of products in its factory at Long Crendon, Buckinghamshire.

Visit Thame Workholding

Stand J200