- 2nd February 2023

- Manufacturing, Southern

- Southern 2023

Sempre Group explains how connected metrology boosts productivity

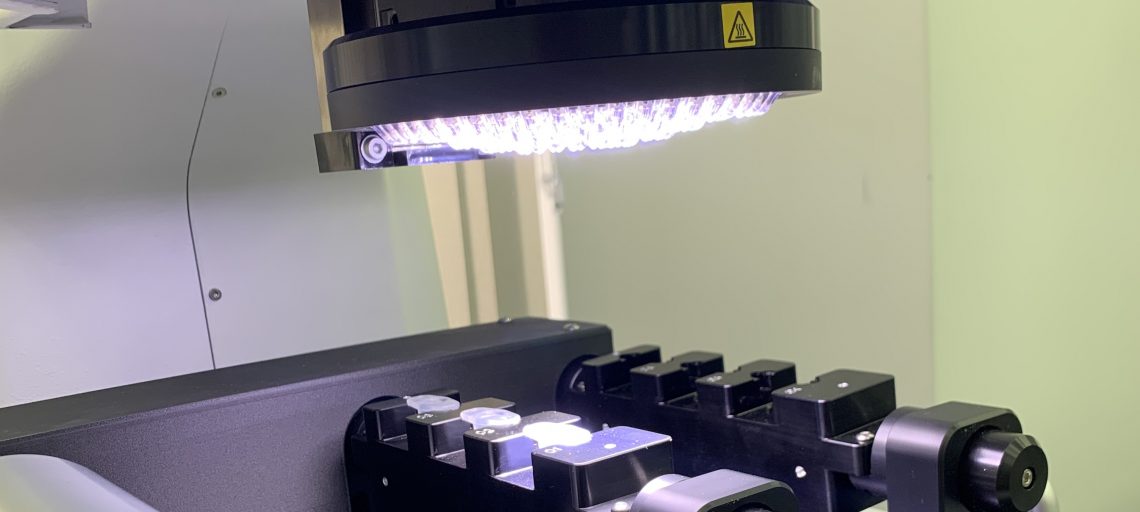

Connecting automated metrology systems and software improves productivity, says Sempre Group. Visitors to the stand will see the whole quality process completed with little operator intervention or opportunity for error, from auto-ballooning a drawing, generating inspection plans, loading parts and automating measurement as well as importing results directly into FAIR/PPAP reporting templates. They will also see how to get more accurate and repeatable results with the latest technology and additions such as fixturing.

Connecting automated metrology systems and software improves productivity, says Sempre Group. Visitors to the stand will see the whole quality process completed with little operator intervention or opportunity for error, from auto-ballooning a drawing, generating inspection plans, loading parts and automating measurement as well as importing results directly into FAIR/PPAP reporting templates. They will also see how to get more accurate and repeatable results with the latest technology and additions such as fixturing.

Metrology experts will be on the stand to advise on using these technologies to automate quality assurance and how to implement it at each stage of production.

The stand will also feature Micro-Vu CMM, Opticline shaft measurement, Sensofar optical profilers and the High QA Inspection Manager. This automated software allows users to scan entire drawings and extract geometric dimensioning and tolerance (GD&T) data, as well as import inspected results from any co-ordinate-measuring machine (CMM).

Visit Sempre Group at Southern Manufacturing & Electronics 2023 – Stand E270