- 6th February 2019

- Exhibitor Announcements, Manufacturing

- South2019

New vacuum furnaces increase heat treatment capability

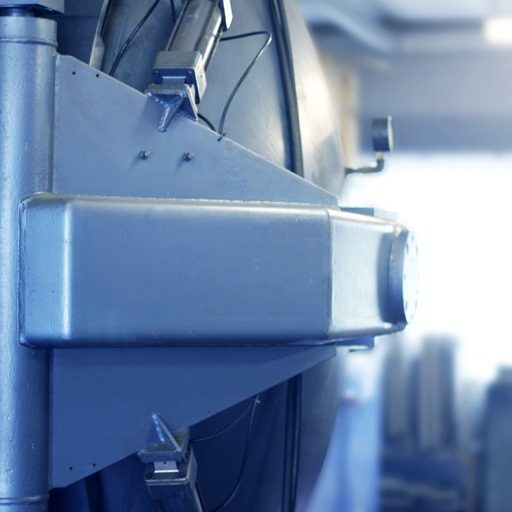

Created from the acquisition of CNC Vacuum Processes by the Magnetic Shields group, MSL Heat Treatment has built on the legacy of quality vacuum heat treatment and brazing. It has invested heavily to refurbish and replace vacuum furnaces to meet the demands of modern manufacturing. It has commissioned two vacuum furnaces with the latest control and data acquisition technology designed to meet NADCAP standards. The company has also committed to improving the quality management system, ISO9001:2015 and is working towards AS9100 RevD.

It exclusively operates vacuum furnaces to produce processes that are highly consistent, repeatable and clean, with minimal distortion and dimensional changes on treated parts. Vacuum brazing processes are also ideal for applications demanding these qualities. When designing complex assemblies it has many advantages over traditional joining techniques, says the company. As well as being able to join dissimilar metals in a controlled way with high joint strength and integrity, it is also useful for large batches of components or parts with many joints that can all be brazed at the same time, potentially lowering per-unit cost of the joining process.

Visit MSL Heat Treatment on stand F175 or go to www.mslheattreatment.co.uk