- 10th January 2019

- Exhibitor Announcements, Manufacturing

- South2019

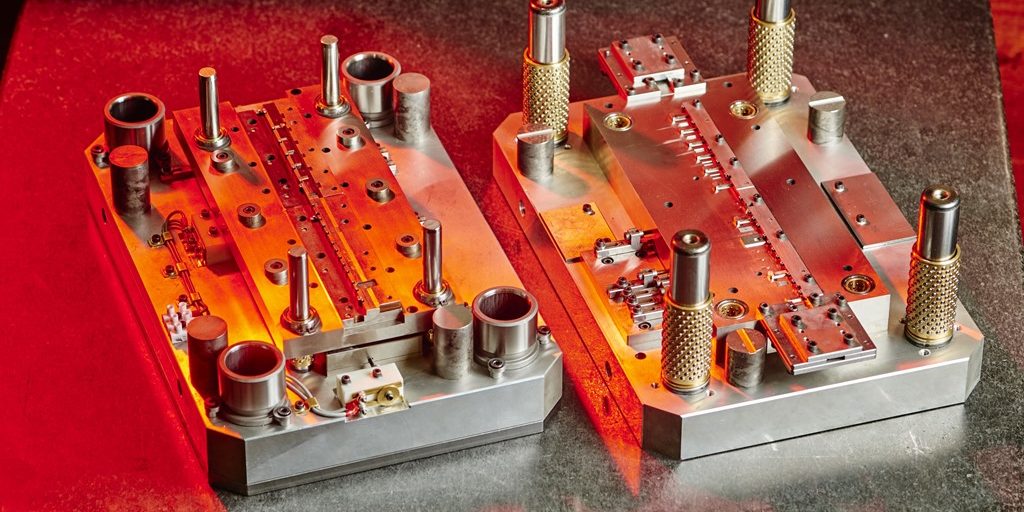

Brandauer examines in micron detail

Stamping and presswork specialist, Brandauer, is proving that the best things in manufacturing come in small packages. It has invested heavily in new high-speed presses, ancillaries, grinding machines and the latest laser inspection equipment for the production of stamped metal components.

Accuracy to a tolerance of 20µ is paramount when making parts for the next generation electric engine or military drone.

The company’s ‘What is a Micron’ video will be shown at this year’s Southern Manufacturing show, to provide an in-depth look into the technical aspects of precision metal stamping, the importance of producing to exact tolerances, the materials involved and the end applications.

“A human hair is 50 microns thick so that gives you an idea of the parameters we are working towards,” commented Graham Allison, technical sales manager. The company has recently secured several major contracts in the UK, Europe and the USA.

The company will also be showcasing EloPin press-fit technology, which allows the solderless connection of terminal pins to a PCB, for automotive electronics and any customers looking for robust interconnects.

Visit Brandauer on stand E190 or find out more at www.brandauer.co.uk