- 10th November 2021

- Auto/Aero, Electronics, Exhibitor Announcements

- Components, Connectors, South22

Battery connects for aerospace take off

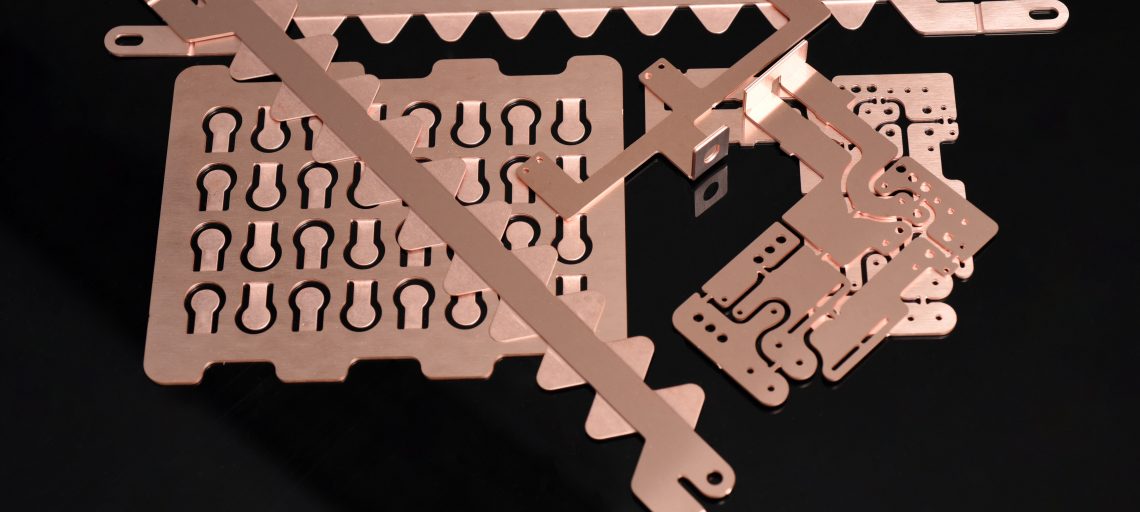

Volumes in the automotive and aerospace sectors have increased rapidly in the race for vehicle electrification, reports Advanced Chemical Etching (ACE), creating exciting new opportunities for titanium, copper and aluminium etching expertise in applications such as battery interconnects. The technology is vitally important in the development of energy management in existing and future electric vehicles, and will be showcased on the firm’s stand at Southern Manufacturing & Electronics 2022.

The company specialises in the development of prototype components, pre-production and volume fulfilment to customers in aerospace, space, precision engineering, automotive, electronics, medical, telecomms and renewables. Activities ranges from safety critical components for aircraft and F1 cars to meshes and electronic connectors, battery interconnectors, fuel cell bi-polar plates and heat exchangers. It works to the most exacting tolerances and can manufacture components in materials, such as stainless steel, nickel alloys, copper, beryllium copper, phosphor bronze, brass and – thanks to ground breaking new processes – aluminium, molybdenum, titanium, nitinol and elgiloy.

Visit Advanced Chemical Etching – Stand C190