- 30th November 2023

- Manufacturing, Southern

- Machinery, southern 2024

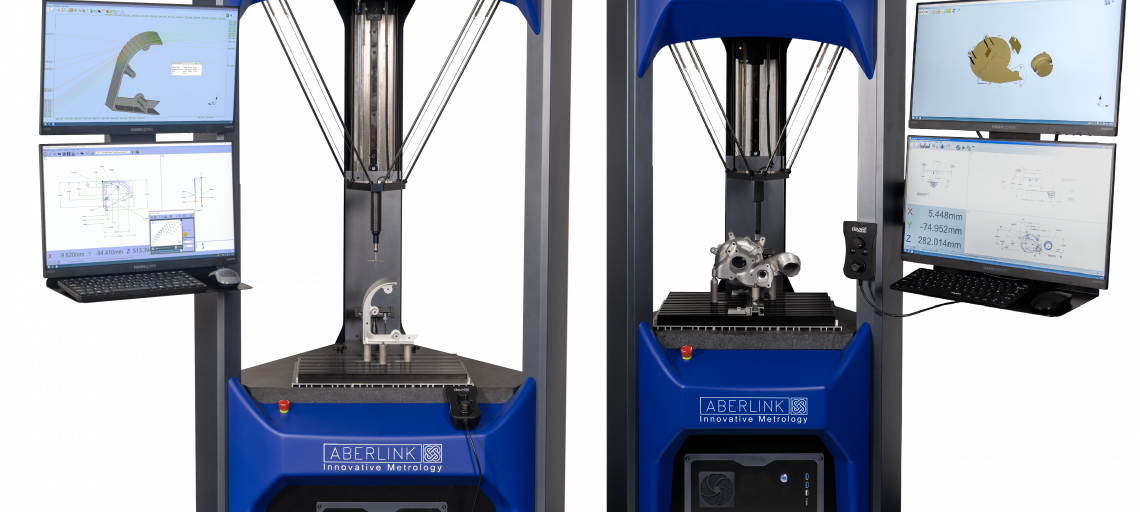

Aberlink unveils CMM with a delta mechanism

The Extol (pictured) is claimed to be first CMM to use a delta mechanism. Available from Aberlink Innovative Metrology the robust machine is able to run around the clock and can be positioned next to a machine tool, in a manufacturing cell, or used in a dedicated inspection area, advises the company.

The Extol (pictured) is claimed to be first CMM to use a delta mechanism. Available from Aberlink Innovative Metrology the robust machine is able to run around the clock and can be positioned next to a machine tool, in a manufacturing cell, or used in a dedicated inspection area, advises the company.

It is equipped with five temperature sensors to monitor both the machine and ambient temperature while software produces a warning if the temperature changes at a rate that is not conducive with reasonable metrology practice.

Aberlink also offers the Fulcrum, a manual CMM employing a three rotary axis design. This is designed to inspect part through every step of the manufacturing process. It is a compact and portable design that can be used on the shop floor, near machine tools.

It is designed to optimise inspection as parts come off the machine one op at a time, feeding back to the machining process at the earliest opportunity, before final inspection. It has a simple user interface for its measurement software and no prior operating experience is required, says the company.

Also available is the Axiom too CNC CMM, available in four different sizes and with Y axis travel up to 1200mm. It can be used with touch trigger probe, continuous contact scanning probe or with the company’s non-contact camera system.

The aluminium bridge structure ensures low inertia and high acceleration and that the temperature of the machine rapidly follows the temperature of the room. The granite and aluminium table provides fantastic natural damping of high frequency vibration; the granite Y rail allows pre-loading of the bridge air bearings in both directions.

Visit Aberlink Innovative Metrology

Stand K205