- 18th February 2019

- Exhibitor Announcements, Manufacturing

- South2019

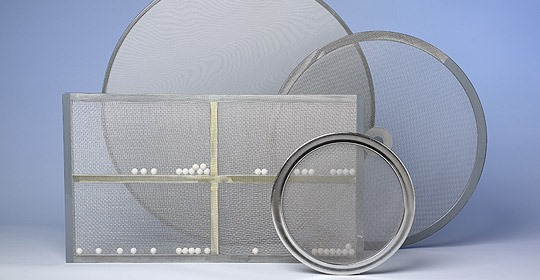

Precision meshes from G Bopp meet challenging applications

For many decades, precision woven meshes from G Bopp have provided quality and accuracy in industries and applications worldwide, says the company.

Its core competence lies in the weaving of fine meshes using stainless steel. The SI range was developed specifically for sieving and sizing operations, offering high levels of weaving accuracy, regularity and definition with above average thermal and corrosion resistance. According to the company, compared to polyester meshes, the range provides excellent throughput combined with a long service life and reduced downtime.

The FI filtration and separation mesh range includes medium, fine and ultra-fine filter meshes, produced by weaving machines, in clean and air conditioned halls.

A comprehensive range of sintered meshes includes single layer (DKS) meshes and multi-layered material. Dependent upon requirements, both meshes and sintered products can be fabricated into dimensionally accurate components and semi-finished goods.

A range of SD stainless steel meshes has been developed specifically for technical screen printing. They offer optimum print quality with advanced load capacity and service life. Minimal loss of tension during the tensioning and printing processes ensures maximum registration accuracy.

Find out more at www.gbopp.com