- 7th February 2022

- Exhibitor Announcements, Manufacturing

- Components, Plastics, South22

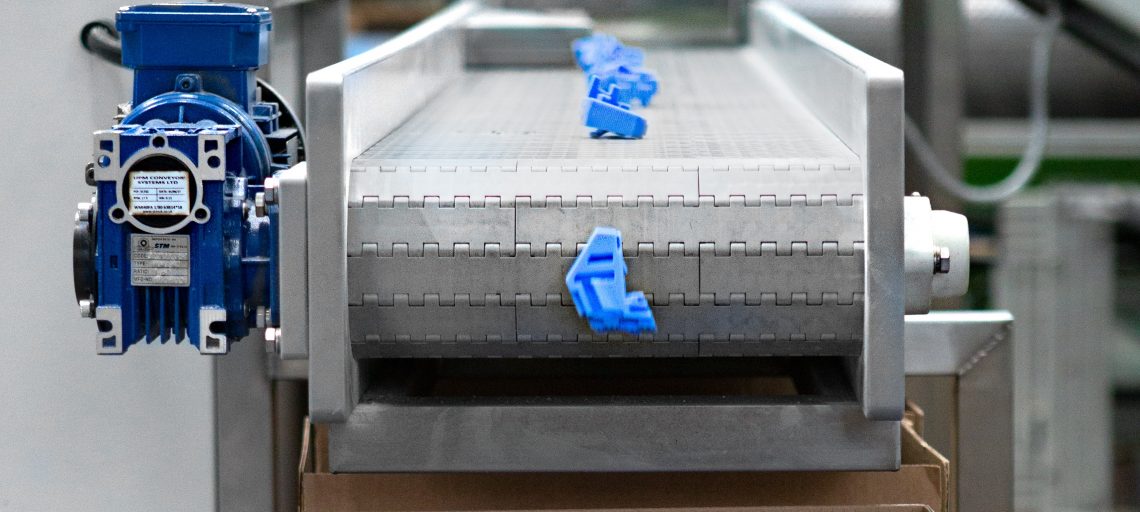

Injection moulding extends to medical and automotive

Since starting injection moulding in 1956, Rutland Plastics has grown but is still a family business, based in Oakham in Rutland. It offers a range of plastic injection moulding services and has over 30 moulding machines on-site ranging from 50 to 1700t. This range provides the ability to produce mouldings from 1g to 48kg and up to 1.5m in size.

The company works in partnership with its customers and offers advice and expert knowledge at all stages of the manufacturing process from design for manufacturing, tooling and through to production. It can also add the finishing touches required for injection moulding projects through a suite of services such as machining, assembly and warehousing.

Customers are from almost all industry sectors, from medical to consumer, construction to automotive and utilities. The company has been involved in the electrofusion methods of joining plastic pipes and has patented one of these processes.

Holder of Investors in People since 1995, it has added Quality Management ISO9001, Medical Devices Quality Management ISO13485 and Environmental Management ISO14001 and is a member of the BPF, GTMA and Make UK.

Visit Rutland Plastics – Stand J315

https://www.rutlandplastics.co.uk