- 7th February 2019

- Electronics, Exhibitor Announcements

- South2019

EMS boasts 100% reliability for automotive

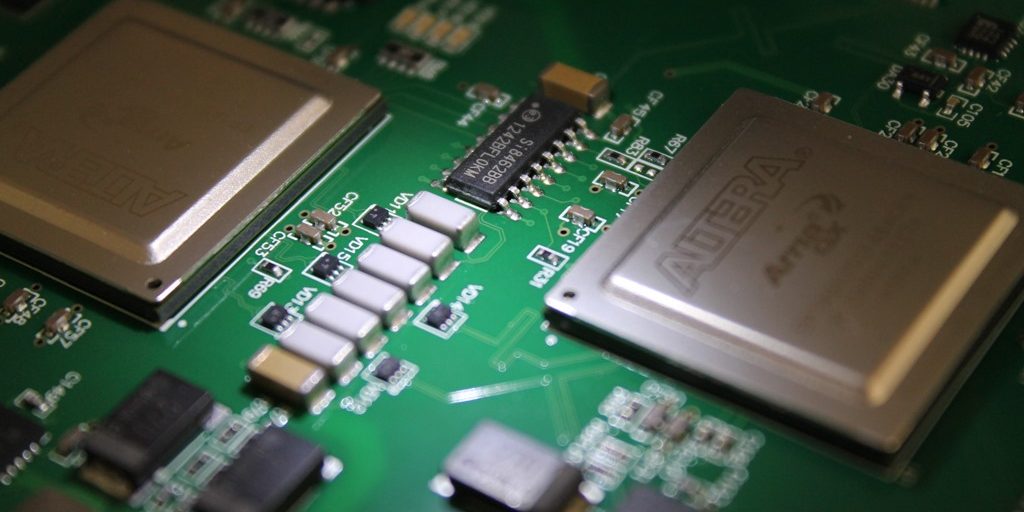

Design, testing, manufacturing and delivery of PCBAs make Volburg a one-stop-shop for OEMs. The EMS company has more than 20 years’ experience in the UK, Germany and Scandinavia.

Services also include industrialisation (adjustment of products for manufacturing process), advanced supply chain for on-time manufacturing and delivery. Expected delivery reliability is 95% for industrial and 100% for automotive customers, reports the company.

The company’s facilities and production equipment adjusted for the assembly of small- and medium-sized production volumes of PCB boards with different levels of complexity. Two SMD lines are used for SMT, 3D AOI quality inspection and Fuji Trax traceability. There are also a reflow oven SMT, ATF wave soldering, SEHO and Pillarhouse selective soldering machines. All soldering processes are conducted in an inert atmosphere using nitrogen.

Programming of controllers, ICT and functional testing is a standard service for industrial and automotive customers. Selective conformal coating line is available, together with potting and encapsulation and semi-automatic mixing/dispensing equipment.

The company is certified to ISO 9001:2015, ISO 14001:2015, IATF 16949:2016 and uses the IPC-A-610F standard.

Visit Volburg on stand D75 or find out more at www.volburg.lv