- 6th January 2020

- Exhibitor Announcements, Manufacturing

- Automation, Machinery, South2020

Cobots from Mills CNC boost productivity

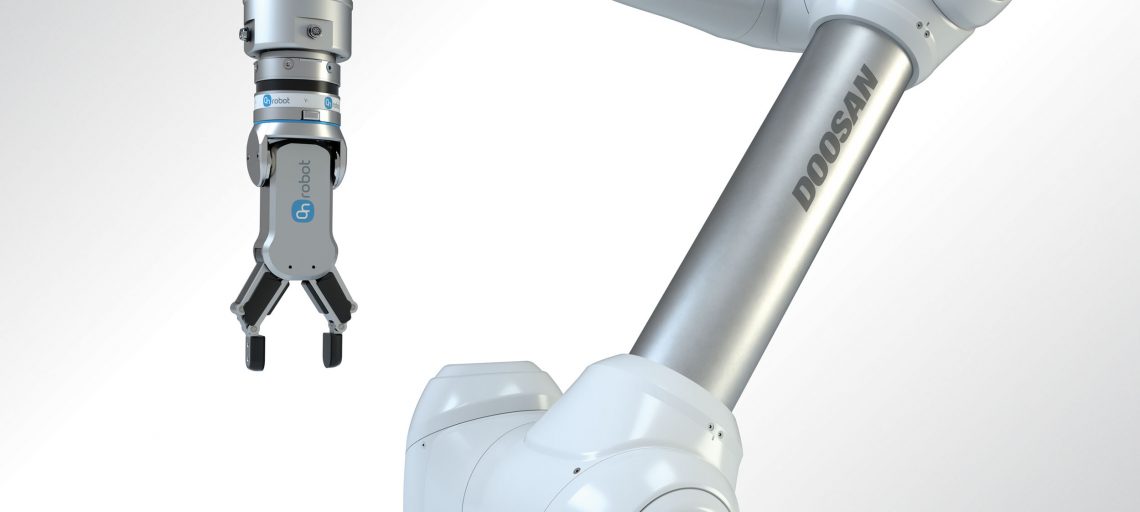

Mills CNC, through its Automation Division, will be showcasing its latest collaborative robot technology, with two cobots being demonstrated live on its stand at Southern Manufacturing 2020, The first, the M0617, is largest cobot in the Doosan range in terms of reach radius (1.7m) and, at the event, will be performing a range of tasks that demonstrate its inherent flexibility and broad application potential.

The second cobot features integrated vision technology which enables it to identify and sort parts by size, shape, orientation, text pattern recognition etc. Typical applications include CNC machine tool tending, testing and inspection, through to packaging, palletising, assembly and ‘pick and place’ operations. According to the firm, Doosan cobots are characterised by their build quality, safety, versatility and ease of use. They are equipped with 6-axis articulated arms with highly-sensitive torque sensors which detect any change in force or pressure, causing them to stop.

There are four different cobots in the Doosan range. Each has a different payload capacity and reach radius, and each is supplied with a state-of-the-art controller and sophisticated and intuitive pendant control. All cobots can be specified with different end-of-arm tooling systems and solutions, and are backed by Mills CNC Automation’s technical, pre- and after-sales service and support.

See the cobots in action on the Mills CNC stand B160 or find out more at www.millscnc.co.uk