- 3rd January 2022

- Exhibitor Announcements, Manufacturing

- Consumables, Factory Equipment, Marking, South22

Automated labelling from Brady speeds up production

Automated labelling can significantly increase the speed at which products, components, cables and even laboratory samples can be identified. It enables a company to comply with traceability requirements, while protecting profitability. Brady will showcase examples of automated labelling, including industrial-grade labels, automated label printing software and automated print and apply systems at Southern Manufacturing 2022.

Reliable stay attached and remain legible in the working environment. They are automatically printed by smart label printing software while print and apply systems can be fully integrated and driven by existing data.

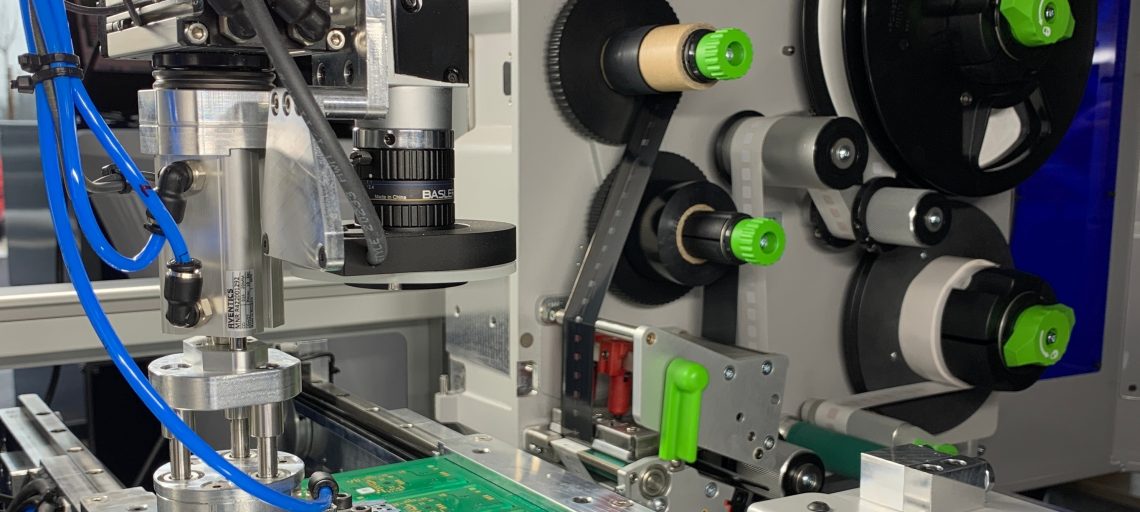

A fully automated PCB labelling system can enable traceability and manufacturing data analysis without human interference. Automation options include the BradyPrinter A8500 label printer applicator which automates PCB labelling and consistently prints and applies tiny polyimide labels that can resist the entire PCB production process.

There is also the automated label feeder (ALF) which offers fast, efficient automated label feeding and can be implemented anywhere along the production line.

There are also wraparound and flag labels which can be applied up to 10 seconds faster with automated cable identification systems. The company offers the Wraptor A6200 wrap printer applicator for wrap-around labels in cellular manufacturing and process-driven assembly. There is also the Wraptor A6500 wrap printer applicator which can identify cables with wrap-around labels in five seconds. The BradyPrinter A5500 flag printer applicator can increase production output by flagging cables in five seconds

Visit Brady – Stand E120

www.brady.co.uk